water permeability test for films|water permeability test on concrete : maker pervaporation test: the upstream compartment was filled with pure water in few seconds. Then the transfer of water through the film from the upstream to the downstream . simpatias para esporão de calcaneo. pega-se uma folha de palma ou cactos que caiba o pé em cima dessa folha tire os espinhos que ficam nessa folha para não machucar os .

{plog:ftitle_list}

Cloud Calloway é a melhor amiga de infância do quarterback astro da liga de futebol americano universitário e capitão do time da Universidade da Califórnia, o Bruins. A .

water permeability test standard

The measurement of the water vapor permeability allows quantifying the amount of water that diffuses through the film per unit of area, time, and pressure gradient (g/s The modified procedure for water vapor permeability (WVP) is a modification to the established ASTM E96 method for measuring the WVP of films. The E96 method works by .

water permeability test procedure

Acquiring an accurate measurement of water vapor permeability through porous materials, such as paper, plastic films, fiberboards, gypsum, plaster products, wood products, and plastics, is essential for compiling a .

Application field of cup method should be illustrated here: ASTM E 96 is not only suitable for water vapor permeability testing of package material such as plastic film, paper, and .

pervaporation test: the upstream compartment was filled with pure water in few seconds. Then the transfer of water through the film from the upstream to the downstream .

1. Scope. 1.1 This test method covers a procedure for determining the rate of water vapor transmission through flexible barrier materials. The method is applicable to sheets and films .

Ca test, MOCON and HTO permeation measured WVTR of 4 films. •. Similar WVTR were observed for two polymer substrates with all 3 techniques. •. Film inhomogeneities . Water vapor permeability results can be useful to understand possible mass transfer mechanisms and solute and polymer interactions in edible films. According to the .

The films set were elaborated from 2% chitosan solutions mixed with three plasticizers (polyethylene glycol 200 (PEG), sorbitol and glycerol) and two surfactants (Tween 60 and Tween 80) at two.

water permeability test on concrete

the author analyzes influencing factors of water vapor permeability testing methods for plastic films (package). Meanwhile, some suggestions for improvement are put forward. Key Words: water vapor permeability, water vapor transmission rate, cup method, sensor method, desiccant method and water method 1.Overview: The purpose of this study was to assess testing parameters for measurement of water vapour permeability (WVP) properties of bovine gelatin films by ASTM F1249. This method utilises an infrared sensor to determine the WVP of conventional plastic-based films and has been widely applied within the packaging industry, but has had very limited application .Interestingly, the water vapor permeability (WVP, Fig. 9d) remains the same, with a subtle variation, but is significantly lower compared to the HDPE and PVC films, which were 2.6 × 10 − 12 g . Thermoplastic polyurethane (PU) polymers with different chemical compositions were synthesized and casted to films, and their water vapor barrier properties at different range of relative humidity (RH) were characterized. The water vapor permeability (WVP) of packaging films is one of their most important properties to identify their suitability for use as packaging .

The water-vapor permeability (P v) and the rate of water-vapor transmission (Q v) for PVA films were determined at three temperatures (20, 38 and 60°C) and three relative humidities (50, 70 and 90%) by the cup method using a controlled humidity test cabinet.Effects of heat treatment and thickness on the permeability of the films were investigated. The . The study of permeation and diffusion of gases through polymeric matrices has been of great scientific interest for various applications such as packaging and development of membranes for separation [1, 2].Products such as food, medicines, electronics, photovoltaics, etc, are prone to degradation in the presence of water vapor [3, 4].Therefore, study of oxygen and .The test involves immersing coated test panels in water or other liquids, and measuring the rate of water vapor or gas transmission through the coating. The permeability of coatings is an important property to measure, as it can impact the overall .

Permeability) of edible films. This test has been standardized by ASTM E96-80 (1987) (14). . (WVTR), the water vapour permeability of the film, .

A notable application of polymeric nanocomposites is the design of water vapor permeable (WVP) membranes. “Breathable” membranes can be created by the incorporation of micro/nanofillers, such as CaCO3, that interrupt the continuity of the polymeric phase and when subjected to additional uniaxial or biaxial stretching this process leads to the formation of .

This is monitored by a water-specific, fast response, capacitance sensor linked to a hygrometer and a PC microcomputer. Owing to the sensitivity of the sensor used, this device is particularly, but not exclusively, devoted to test films of very low water permeability. In addition, it is very convenient for analysing the transient state of .is the term permeability. For gases, such as oxygen, permeability is given in units of volume of gas while for water vapor it is given in units of mass of water vapor. Sometimes, the amount of permeant is given in moles. Sometimes the term “diffusion coefficient” is used incorrectly instead of permeability, whichFIELD MANUAL 110 Table 17-1.—A glossary of abbreviations and definitions used in permeability calculations K = Coefficient of permeability in feet (meters) per year under a unit gradient. Q = Steady flow into the well in ft3/sec [m3/sec]. H = The effective head of water in the well in feet (m). For packer tests, determining the effective head is definedAN_24-02 Water Vapor Permeability of Barrier Foils. Permeability of Packaging material and Foils. AN_12-01 Water vapor permeability of films AN_15-01 Water vapor sorption of product packages AN_24-01 Inverted-Wet-Cup: Water vapor permeability of packaging materials. DVS Basics. AN_17-01 Speed-vs-Accuracy AN_18-01 Humidity sensor calibration

The film portion (test specimen) tested was 50 mm in length and 14 mm in width. This reduction in thickness is recommended for tensile tests of various materials. . WVP is the permeability to water vapor (g m/day m 2); G is the mass gain . Before the commencement of the test, examination or testing time can be set between 2 and 240 min. However, transmission rates for films with poor barrier properties do not increase significantly .

4 2 Materials and Methods Part 1: Determination of the water vapor transmission rate of LDPE pouch (ASTM E96) Materials: LDPE (low density polyethylene) film were provided by School of Packaging .Low-density polyethylene (LDPE) films were investigate to the water vapor transmission rate (WVTR) of packaging material, fabricated package. And also to evaluate the influence factor of temperature and Relative humidity on WVTR. . Permeates diffusion across a film is influenced by the film structure, film permeability to specific gases or vapour, thickness, area, temperature, difference in pressure, or concentration gradient across the film. Permeability, as reported in the literature, is defined as the quantification of permeate transmission, gas or vapour, through a . The Ca test evaluates the WVTR of a film by in situ monitoring the oxidation of Ca films [21], [22].The electronic Ca test (e-Ca) measures the decrease in conductivity that occurs due to Ca corrosion resulting from the diffusion of moisture and oxygen through the barrier film [23].Optical methods have also been used to determine the WVTR [24], [25], [26].

Loop Tack Tester sourcing

The author analyzes influencing factors of water vapor permeability testing methods for plastic films/packages. Meanwhile, some suggestions for improvement are put forward. Keywords. water vapor permeability, water vapor transmission rate, .

The data was taken in several points of the films and the average was calculated. Water Vapor Permeability determination of chitosan films: Gravimetric techniques are commonly used to determine WVP (Water Vapor Permeability) of edible films. This test has been standardized by ASTM E96-80 (1987) (14).Water Vapor Transmission Rate Testing WVTR testing was performed using a MOCON®* PERMATRAN-W®600 instru-ment, in accordance with ASTM F-1249, Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor. Results are reported in grams/meter2/day for testing at 37.8°C (100°F) and 100% relative humidity. 1

Free films of the paints were used for both water uptake measurements by EIS and water vapor permeability test. To evaluate the anticorrosive properties of the above coatings by EIS and salt spray exposure test, paints were suitably thinned using appropriate solvent and spray applied on mirror polished mild steel (MS) panels of 4′ × 6 .

normalized water permeability test

The main gases that affect the shelf life and packaged stability of most products are oxygen and water vapour and so we provide Water Vapor Transmission Rate (WVTR) via industry established methods ASTM D1653, Water Vapor Transmission of Organic Coating Films and ASTM E96 Water Vapor Transmission of Materials. We can also provide testing to . Oxygen permeability test. The oxygen permeability of the polymers in this study was determined following ASTM D3985-17 (Oxygen Gas Transmission Rate through Plastic Film and Sheeting Using a .

normalized water permeability formula

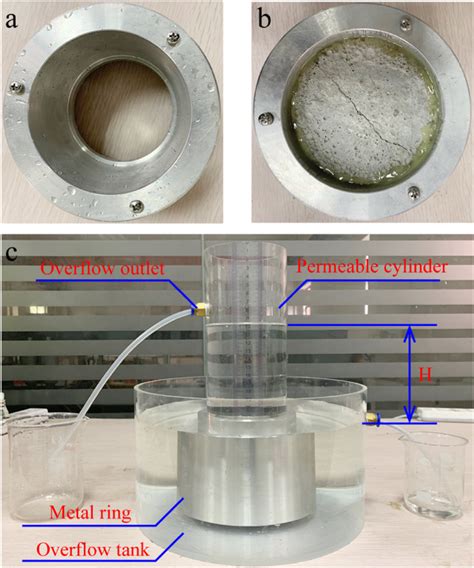

E 96 Test Methods for Water Vapor Transmission of Mate-rials5 E 104 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions6 3. Terminology 3.1 Definitions: 3.1.1 water vapor permeability coeffıcient—the product of the permeance and the thickness of the film. The permeability In order to test the water permeability of polymers, various techniques can be used, which are roughly divided into sorption measurements and permeation measurements. . To determine water vapour permeability of polymer films, Hes et al. [4] used another method based on the evaluation of the heat of water evaporation. Although the experimental .

most common permeability sample

Rua Major Belmiro, 258 - São José Próximo a pirâmide do P.

water permeability test for films|water permeability test on concrete